Supply of Spares & Replacement Parts

Component Repair Services

Powered by its strong infrastructure, MTPS offers comprehensive gas turbine repair services. Our gas turbine component repair and rehabilitation shop has the capability to upgrade components to latest standards within extremely quick turnaround times. Our repair workshop provides repair services for the following components for: Fuel Nozzles, Flow Sleeves, Bullhorn Brackets, Crossfire, Tubes & Retainers, Combustion Liners, Transition Pieces, Nozzles, Buckets (outsourced), Shrouds

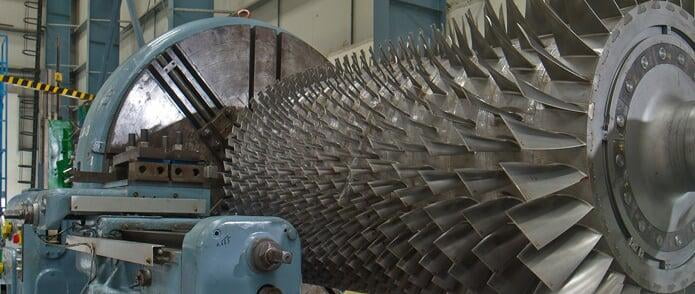

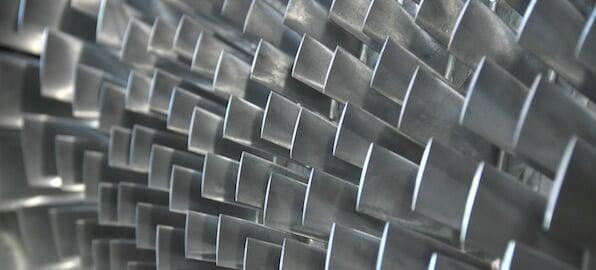

Rotor Repair & Complete Overhaul Services

To complement the existing capabilities of component manufacture, repairs, field services and spares supply capabilities, MTPS inaugurated its Rotor Overhaul facility in the year 2012. The facility has the capability of complete turbine and compressor rotor de-stacking, refurbishment, re-building and balancing.

Field Maintenance & Engineering Services

MTPS employs a wide range of experienced gas turbine, steam turbine & compressor field engineers, technical advisors, and construction and logistic managers to undertake and deliver both on-site and remote engineering services. These services can be complemented to include customized spares packages and tooling kits for regular Combustion, Hot Gas Path and Major Inspections. Our engineering services include: Operation and Maintenance, Electrical & Mechanical, Engineering support, Fuel Conversions, Inspection and Plant Overhaul, Machine up-rate and Improvement

Service

We take great pride in our service team; our project leaders, engineers and supervisors have an accumulated experience of hundreds of years. This experience enables us to perform on-site overhauls or repairs in a unprecedented efficiency. The chance that a damage or a problem is encountered that we have not dealt with is very slim.

Spare Parts / Re-Engineering

Repair

MTPS has the competence to repair rotary and stationary parts both on site or in our workshop. Typical repairs are amongst others: turbine rotor reblading, turbocompressor de/restacking, NDT inspection, seal strip replacement, balancing, bearing repair, shaft and bearing journal repair, control and stopvalve overhaul.